Defence

Our key expertise in the defence sector are gearboxes and gearbox systems for all types of naval ships. Here we look back on more than 20 years of design experience. Our customers include naval architects and shipyards.

For defense projects, our development process follows the requirements of the standards MIL-G-17859 and MIL-STD-882E. The results of design reviews described there are fully documented and made available to the customer.

Our services include:

- Development of new types of propulsion systems

- Design of lightweight gearboxes with power split (for example locked train gears, such as dual tandem articulated and triple tandem articulated gears DTA and TTA)

- Performance increase or functional extension at existing gearboxes

- Analytical proof of shock resistance, quasi-static acc. to BV043 and dynamic (DDAM)

- Minimization of airborne and structure-borne noise by means of primary and secondary measures

- ILS

We develop gearboxes and gearbox systems for single- and multi-engine propulsion plants with diesel engine, gas turbine, steam turbine, electric motor.

We master the high functional complexity of the following propulsion systems:

- CODAD

- COGOG / COGAG

- CODOG / CODAG

- CODLAG

Examples of completed customer projects:

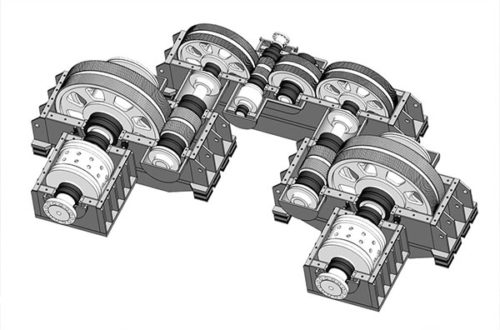

CODLAG System

Two-stage CODLAG gear system for a gas turbine / electric motor propeller drive.

The system consists of a cross-connect gear, which transmits the power of the gas turbine to the two main gears Port and Stbd. Each of the two main gears is connected with the associated propeller Port and Stbd via a hydraulically actuated multi-disc friction clutch. For the electric motor propulsion mode, the complete gear system can be disconnected from the propeller shafts.

In order to minimize transmission of structure-borne noise to the ship’s foundation, all gearboxes are supported on double-elastic resilient mounts.

Power of gas turbine: 38’000 kW.

Power of electric motors: 2 x 1’800 kW.

Weight of complete gear system: 114 tons.

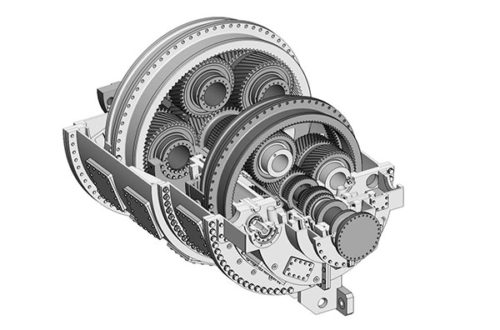

Steam turbine propulsion

Two-stage planetary gearbox with double helical gears for a gas turbine propeller drive.

The two planetary stages are double-joint coupled for free radial and axial self-alignment of the wheels. All planet gears are supported by wear-free journal bearings. A turning gear device for maintenance purposes is integrated in the gearbox.

Power: 32’000 kW.

Gearbox length: 3.2 m.

Gearbox weight: 28 tons.