Aviation

Our customers in the aviation sector focus on the development of turbines, electric motors and propellers, and make use of Novagear’s services for feasibility studies, prototype testing and basic research.

For aviation projects, our engineering process follows the requirements of European Standard EN 9100. Activities such as

- requirement engineering

- analysis of error risks and maintainability

- verification against customer and airworthiness requirements

are fully documented and the results provided to the customer.

Our customers are EASA-approved design organizations and are responsible for the certification of our designs according to EASA Part 21 DOA.

Features of our gear solutions for aviation:

- low power-to-weight ratio

- extremely low noise level through the use of optimized special tooth geometry

- Turboprop engines

- Hybrid turbine-electric systems

- Turbofan

- RPAS (UAV, UAS)

- Drones

- Auxiliary power units (APU)

- Micro gas turbine generators

Examples of completed customer projects:

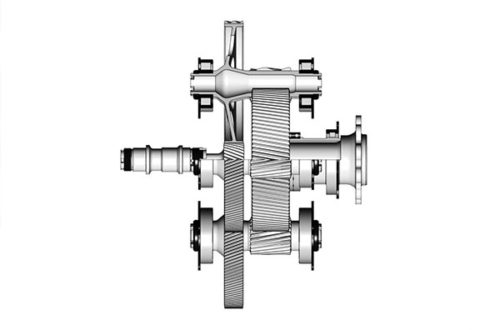

Turboprop engine

Two-stage parallel shaft gearbox with power split for a turbine-propeller drive.

The variable pitch propeller is flanged directly to the output shaft. The output shaft is designed as a hollow shaft and provides space for the hydraulic control device.

Gear ratio: 1:20.

Power/weight ratio of the gear set: 0.1kg/kW.

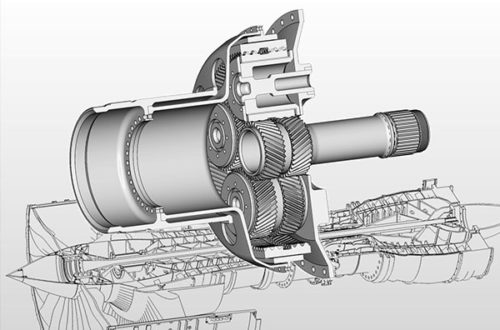

Geared turbofan

Single stage planetary gearbox with 5 planet gears for decoupling the fan and the low pressure turbine.

The interfaces as well as the support for the planetary gears are designed to be flexible. It ensures a uniform load distribution over the tooth width and between the planetary gears in any operating condition.

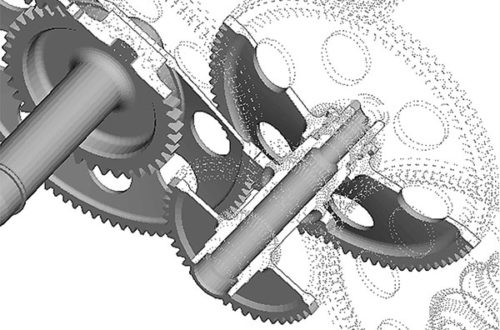

Turbine auxiliary drive

Multi-shaft helical gearbox for the simultaneous drive of oil pump, fuel pump, starter / generator, hydraulic pump and tachometer.

The gear set is weight optimized.

The toothing has a non-standard profile with maximized tooth root rounding and minimized sliding / rolling ratio.

Pitch line velocities 155 and 96 m/s.